Cutting and Packing Solution - Salmon portions

Where precision, efficiency, and food safety go hand in hand

With Scanvaegt’s advanced, integrated cutting and packaging solution, you get a fully scalable and automated line for cutting, packing, and labeling salmon portions —with minimal manual handling and maximum operational reliability

Customized packaging line to suit your needs

Scanvaegt combines expertise in weighing, cutting, and packing into an integrated production line tailored to your specific requirements. Our one-stop-shop concept makes it easy to implement a packing solution that optimizes both operations and resource usage.

With real-time data monitoring, the production can be continuously adjusted, ensuring a streamlined, profitable flow for salmon portioning and packing.

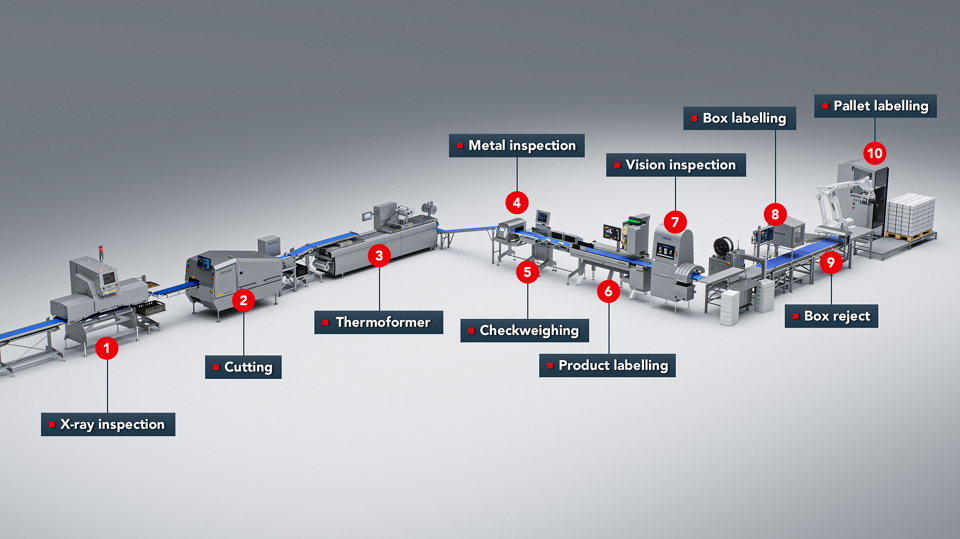

1. X-ray inspection

Before cutting, salmon fillets undergo X-ray inspection to detect large bone fragments or other solid contaminants.

If the system identifies an unwanted fragment, the fillet is automatically rejected. This guarantees high food safety standards and superior product quality.

2. Cutting with ScanCut 400

After inspection, the fillets are conveyed to the portion cutter, ScanCut 400, which cuts the fillets into fixed-weight or fixed-size portions based on customer-specific patterns. Trimmings, such as tailpieces, are automatically removed.

• Adjustable cutting angles: 45°, 60°, 75°, 90°

• High-precision blue laser technology for optimal measurement, thus enabling rapid and highly accurate fixed weight cutting

• Real-time 3D visualization of fillets and cutting patterns via intuitive user interface.

The ScanCut 400 delivers consistent, accurately portioned salmon, maximizing yield whilst minimizing waste.

3. Thermoforming

The individual salmon portions are loaded into a thermoformer for individual form packing and vacuum or MAP (Modified Atmosphere Packing) sealing. This highly automated process, ensures efficient, high-volume retail packing.

4. Metal detection and checkweighing

After thermoforming, the individually packed salmon portions are scanned for metal contaminants and checkweighed on Scanvaegt’s inline Checkweigher.

Any pack with metal contamination or weight outside the tolerance limits is immediately and automatically rejected.

The compact, flexible design of the Scanvaegt Checkweigher allows for seamless integration into most packing lines. Its user-friendly interface provides clear instructions for any required adjustments.

5. Automatic Weigh-Price Labeling

Approved packs are labeled using the Scanvaegt Weigh-Price-Labelling system, which automatically applies accurate weight and price information.

• Fast, precise labeling

• Flexible labeling options to meet different market requirements

6. Vision inspection of sealing and labeling

Unique to this system is an advanced vision sensor that verifies correct sealing and labeling of the salmon packs. This step prevents errors such as leaking seals, unreadable barcodes, incorrect weights, or mislabeling - reducing the risk of costly product recalls.

7. Box labeling

Finished salmon portion packs are automatically boxed. Each box is weighed and labeled, with the system verifying label placement and barcode readability.

8. Palletizing

At the end of the line, boxes are automatically stacked onto pallets, which are then labeled with a final shipping label and prepared for dispatch.

Digital Production Management with ScanPlant

Scanvaegt ScanPlant collects data from all critical points along the production line, providing real-time insights into yield, efficiency and waste. This enables continuous process optimization.

Key Benefits:

• Real-time data for informed decision-making

• Complete overview of yield, waste, and efficiency

• Integration of all processes into a unified data chain

Læs mere om de relaterede produkter i løsningen her:

Why choose Scanvaegt?

Errors in weight, labeling, and sealing can be costly – leading to production downtime, claims, and damage to brand image. Scanvaegt offers a proven and efficient solution that minimizes errors and maximizes efficiency.

Our specialists provide both technical support and guidance – from installation to ongoing line optimization. This ensures more stable operations, lower costs, and higher returns.

Contact our experts on solutions to the food industry

International Business Manager - Food Industry

Automatic weighing systems

+45 4053 4900

Do you have any questions? Request a callback

ScanCare Service – Ensuring High Operational Reliability

Operational reliability is crucial to business efficiency—and, consequently, profitability. Scanvaegt Service provides both preventive maintenance and emergency “first aid” support to optimize the reliability and uptime of your equipment, allowing you to focus on running your business with peace of mind.

With a ScanCare Service Agreement, you gain access to comprehensive service and support resources, helping you ensure optimal performance and maximum uptime of the equipment in your operations.